O-12CA-E8X6S-V1B

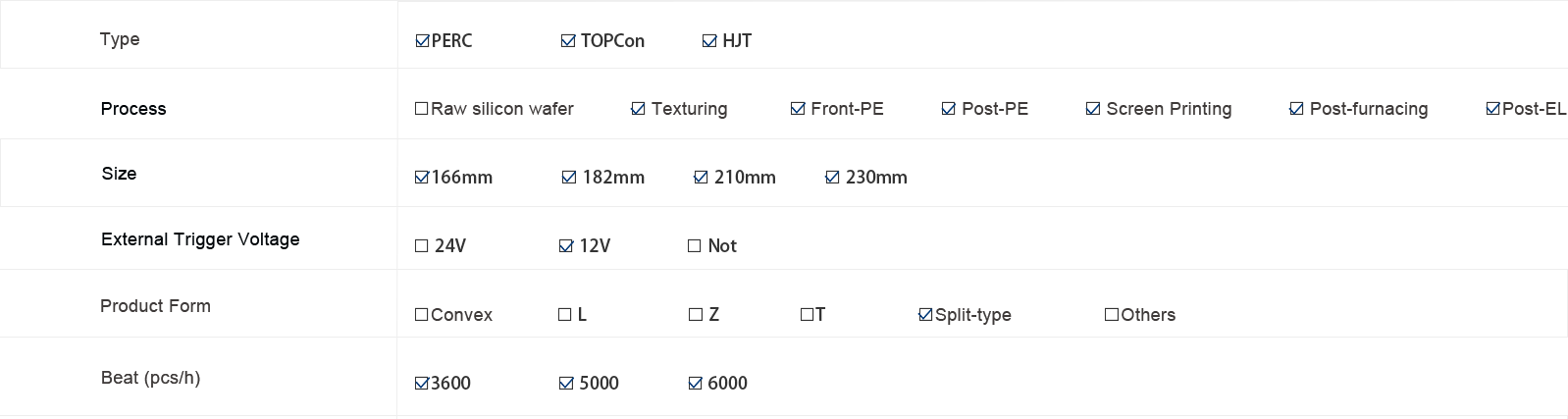

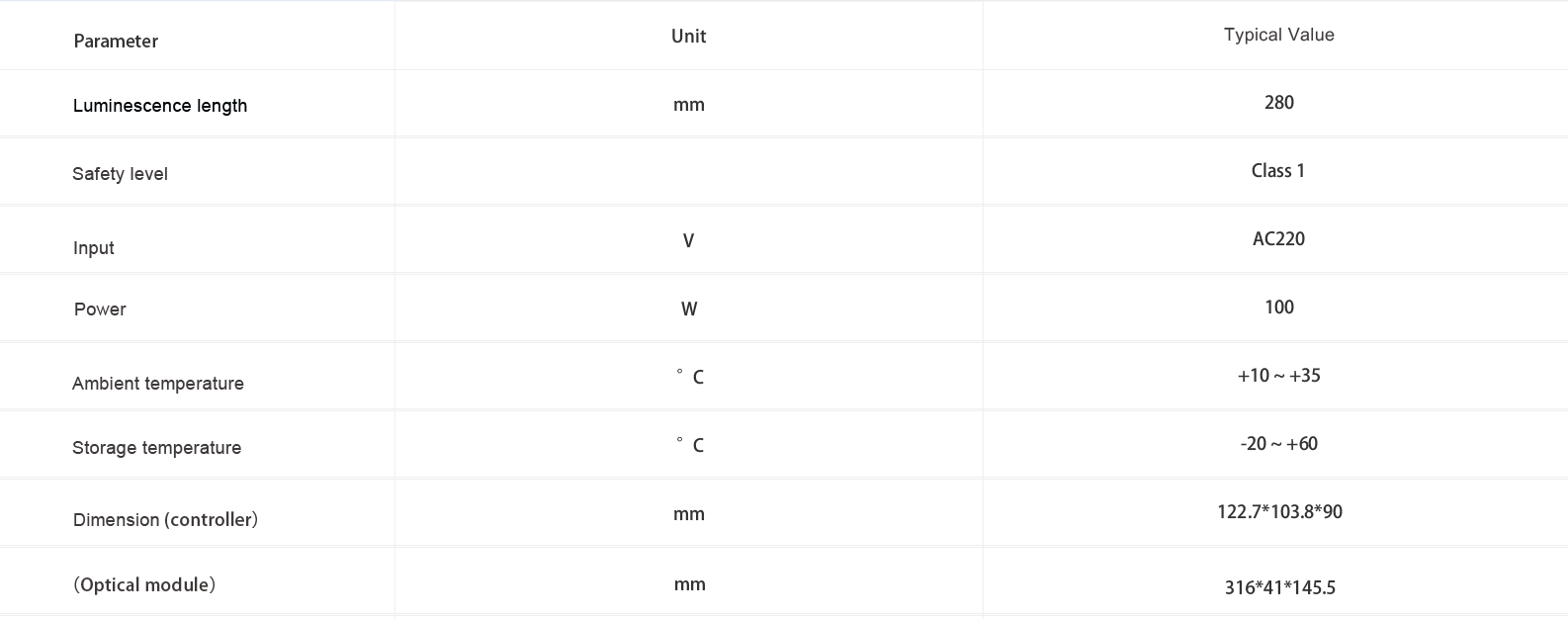

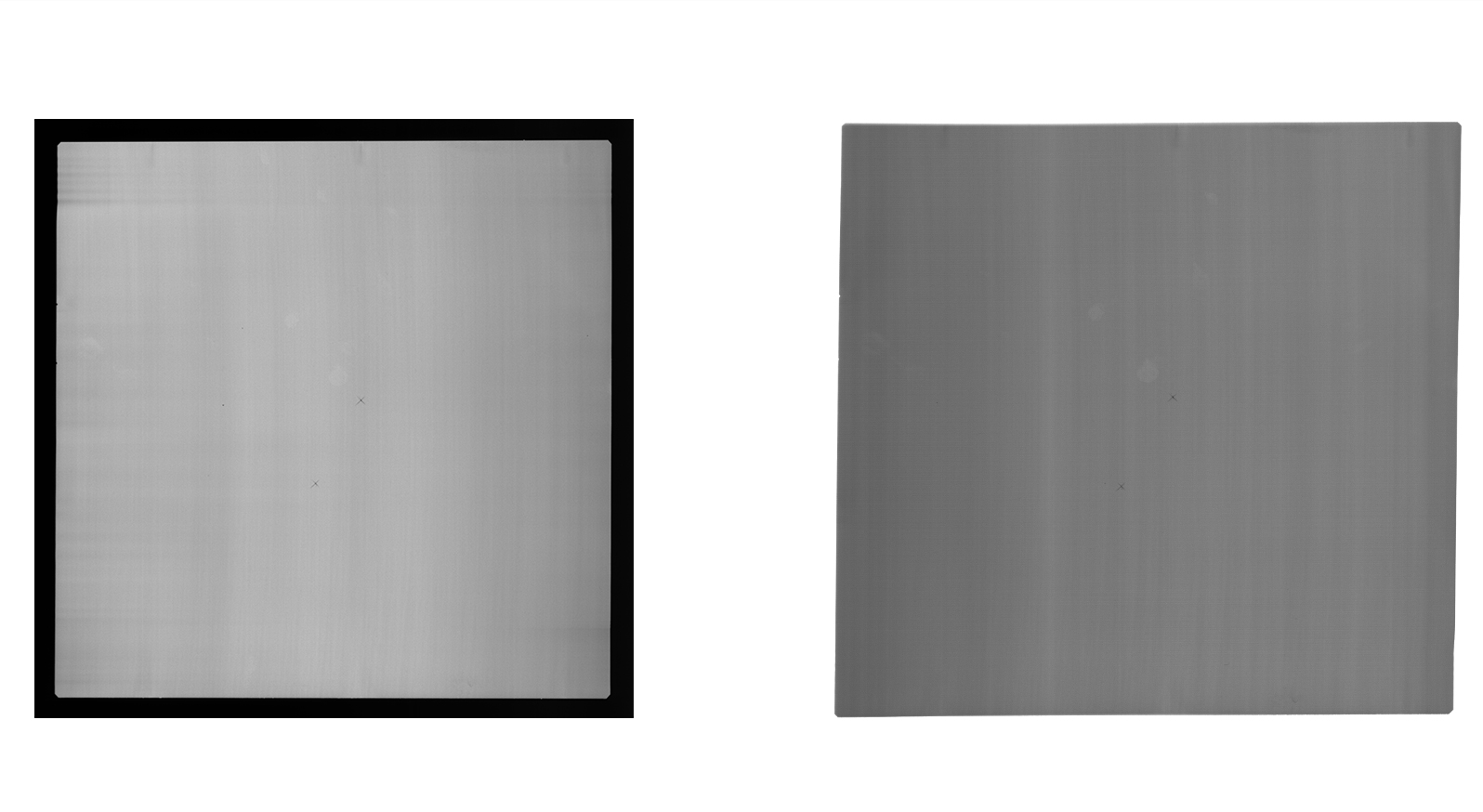

OSI Module is a near-infrared laser light source, matching high-definition line scanning camera. lt is mainly used to detect defects such as hidden crack and missing edges in the whole process.While using,it is necessary to separate the laser source and the line scanning camera on the upper and lower sides of the measured object.With the performance of better direction of the laser,penetrate the silicon wafer and image it at the end of the camera.Laser has the advantages of longer wave-length, stronger penetration, high brightness, highuni-formity and sharper silicon edge imaging.

Besides hidden crack and broken edges, OSI Module can detect a variety of defects such as dirty, finger marks and so on. Users can identify, judge and remove defective products online through computer image recognition technology.

The high-quality imaging of the OSI module combined with a mature image algorithm can be up to 99% detected rate, reduce the back-end fragmentation rate, and save a lot of costs for users. At the same time, it caneffectively control the quality of suppliers' incoming materials and real-time process defect self-inspection.