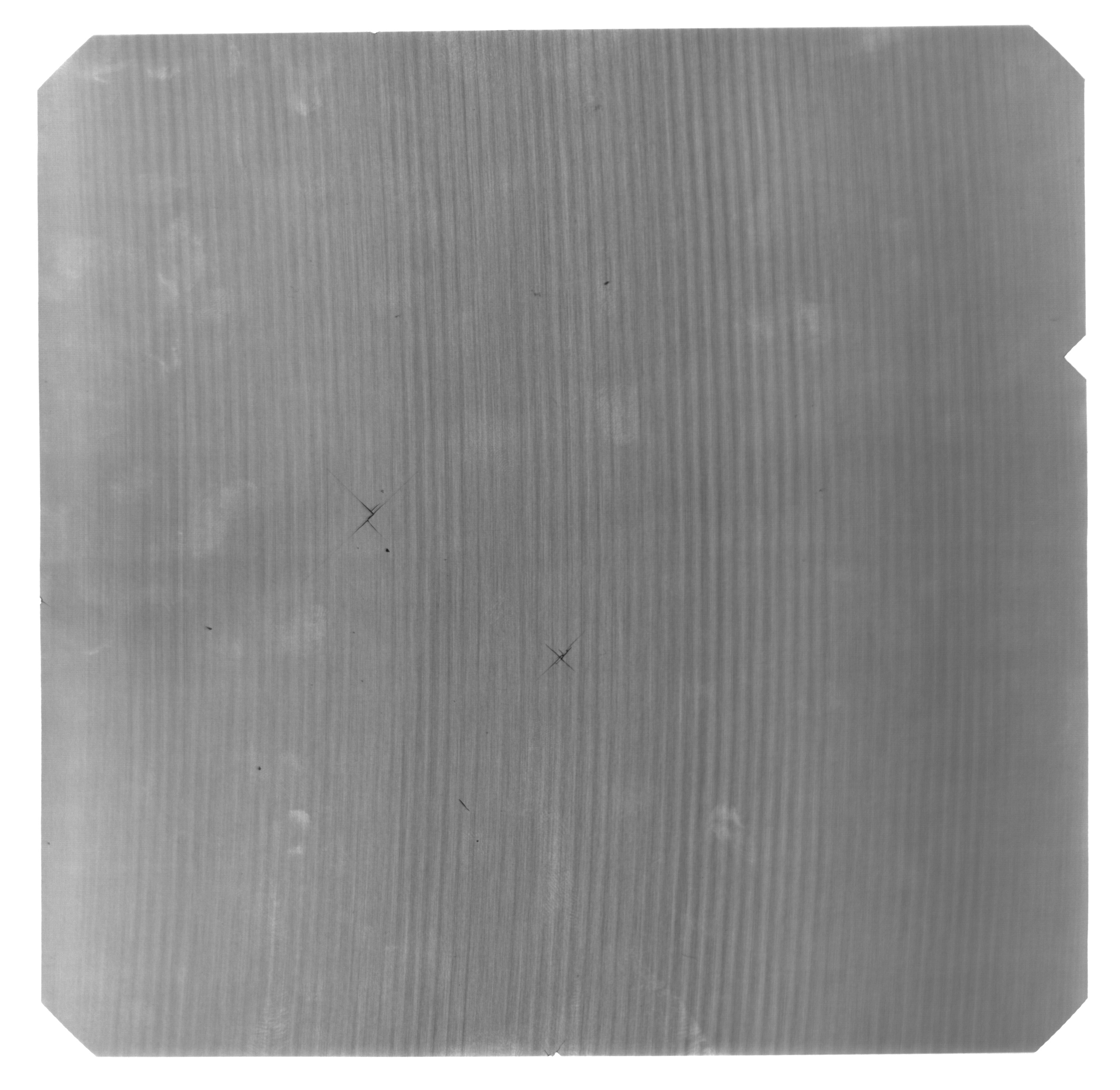

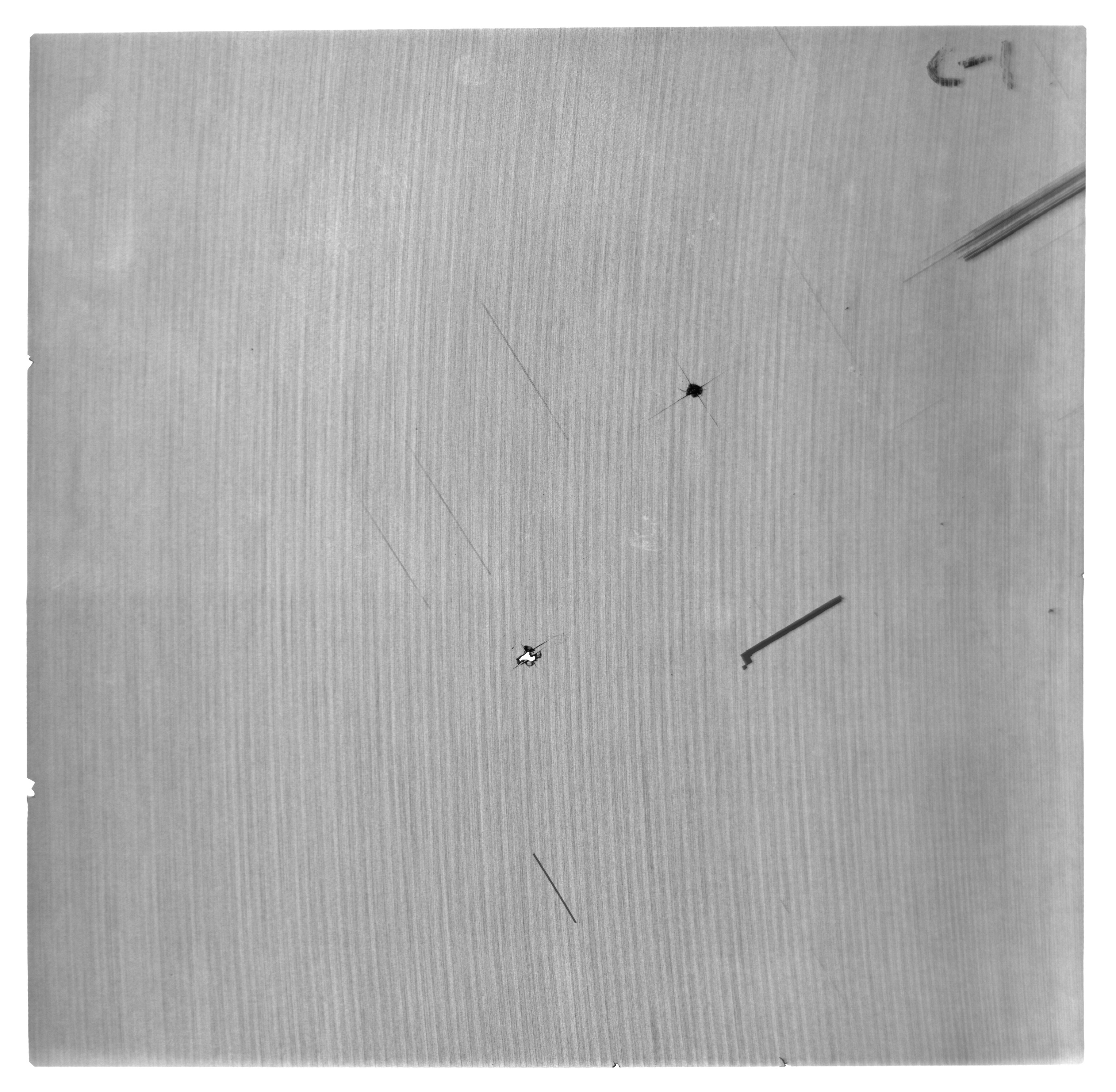

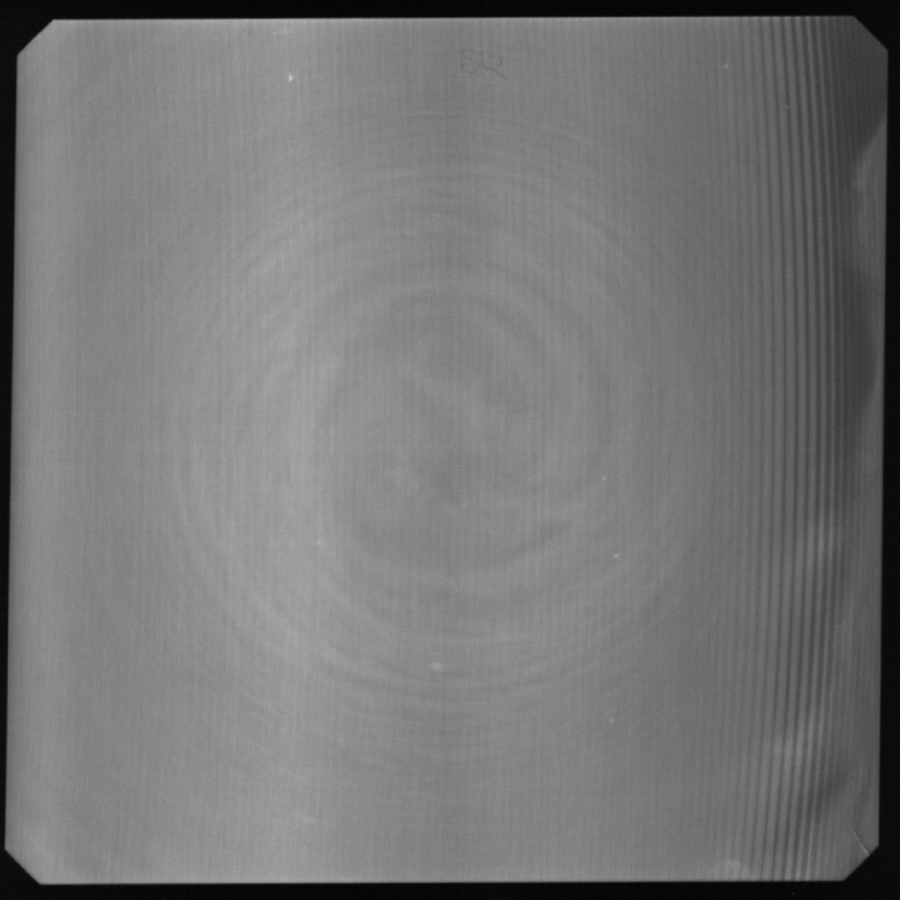

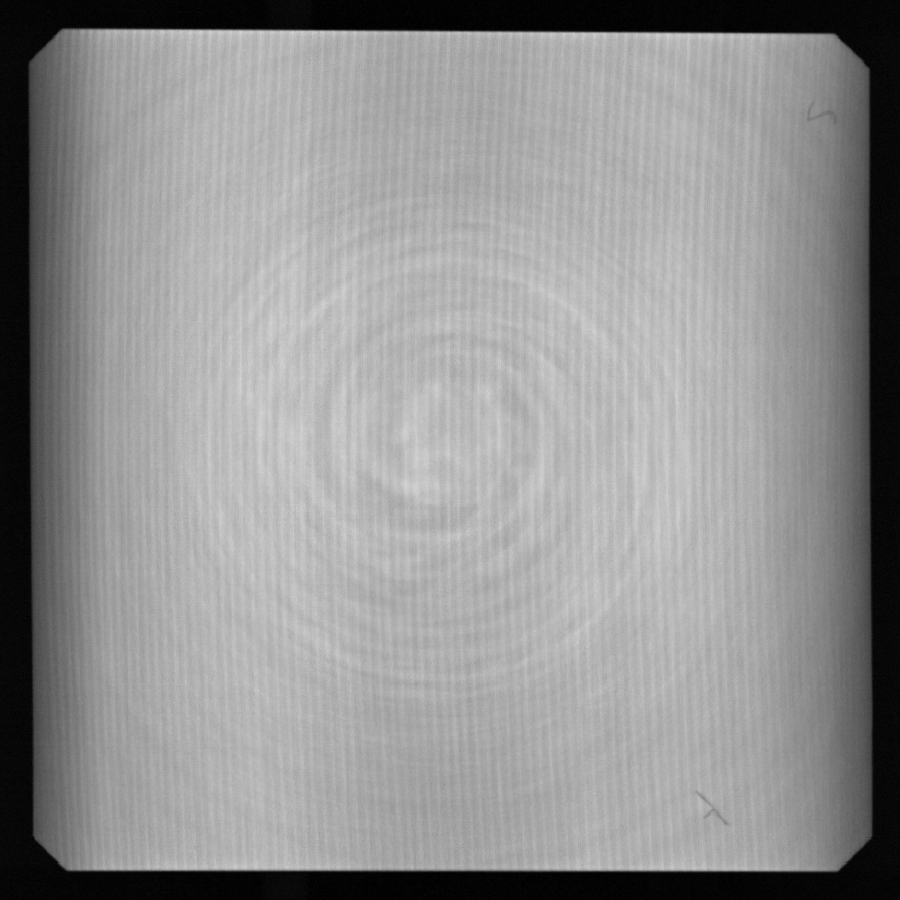

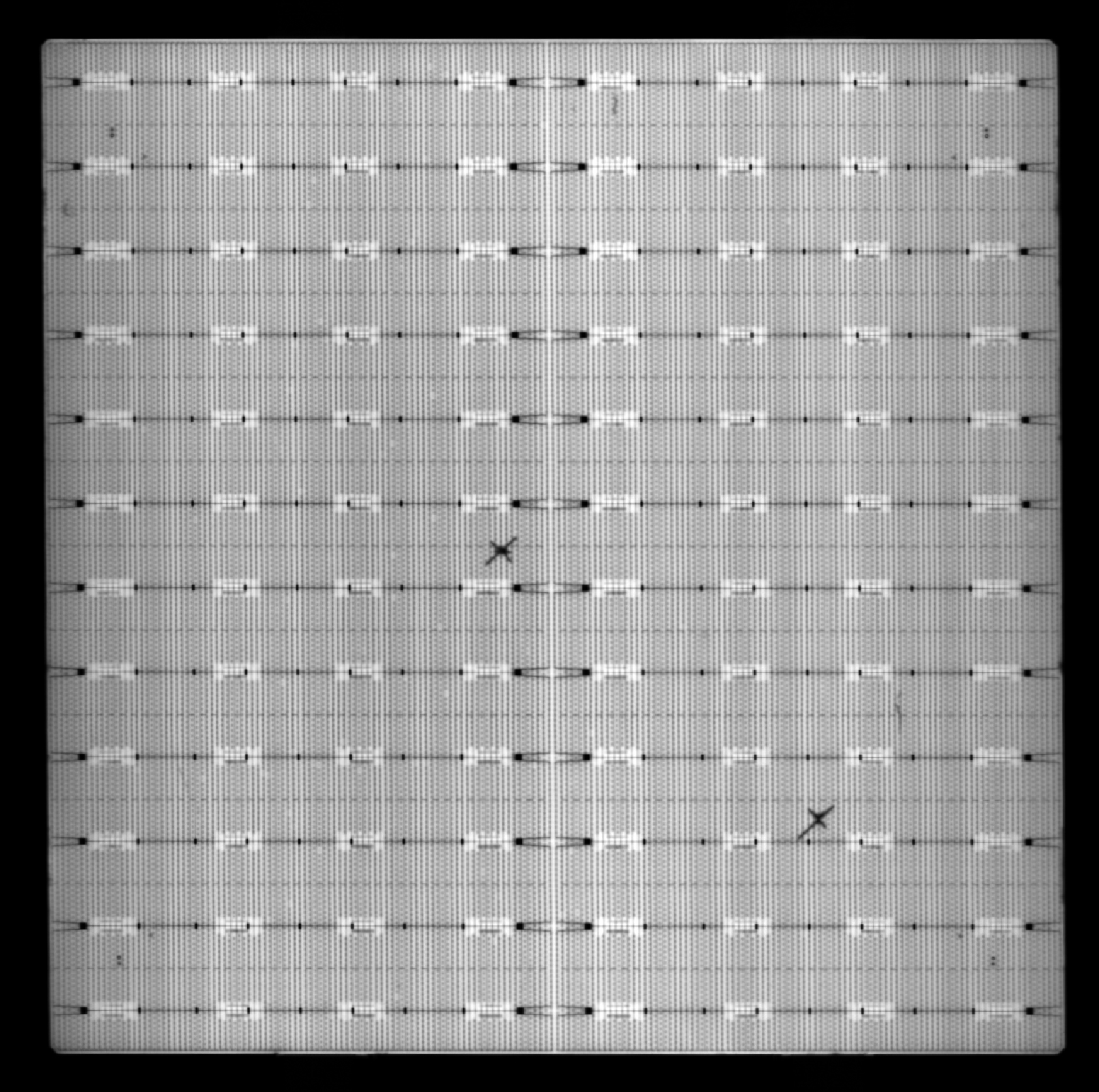

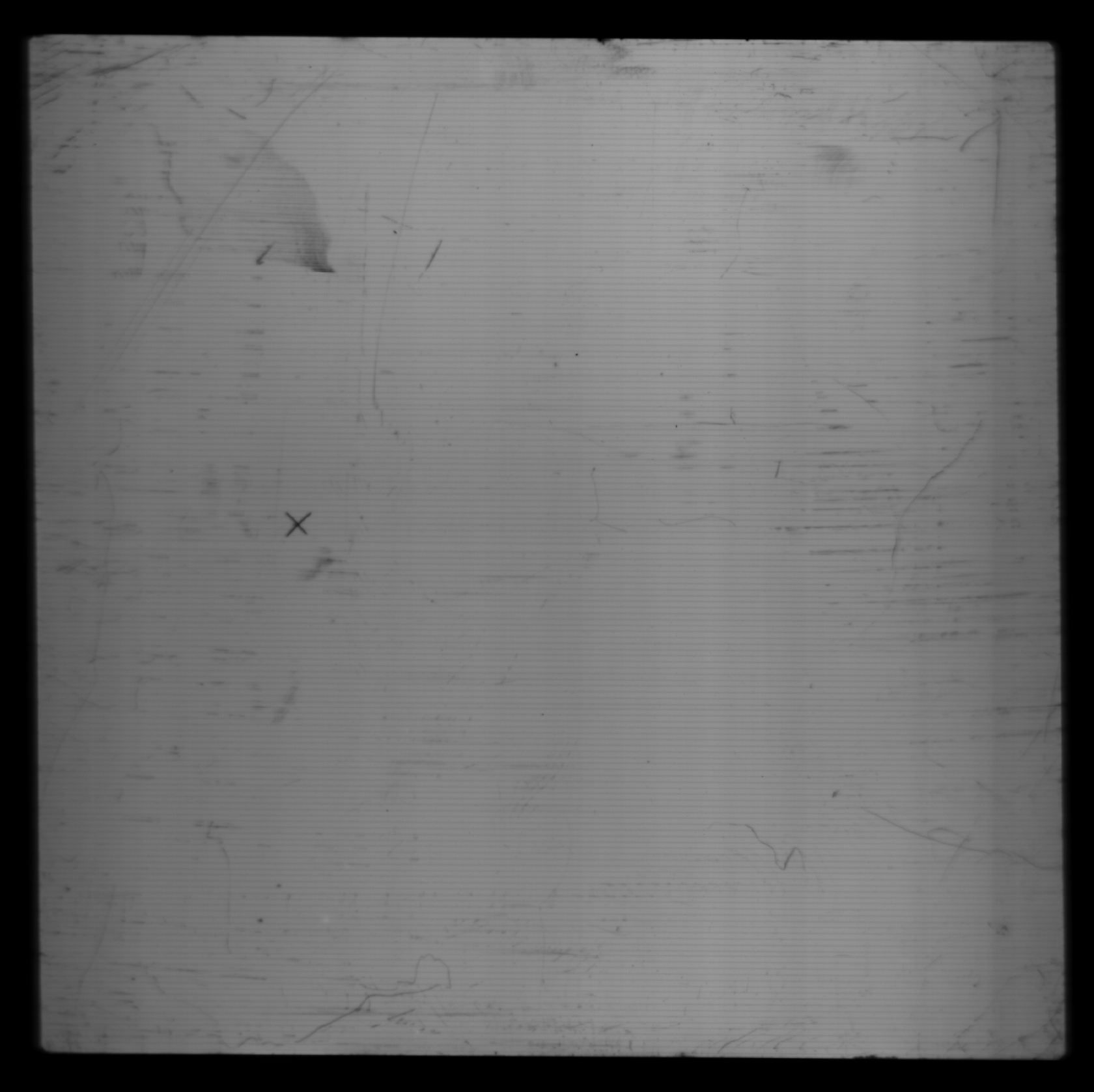

The production process of photovoltaic solar cells includes steps such as raw silicon wafer loading, cleaning, texturing, and etching. The initial raw silicon wafers are mostly provided by silicon material factories. Although these factories have strict control over product quality, batch issues, concentric circles, hidden cracks, and other defects may still occur. Additionally, transportation issues may lead to unavoidable defects such as hidden cracks, chipped edges, and contamination.

Based on the aforementioned defects, if they can be detected early, on one hand, they can be returned to the factory for replacement, and on the other hand, they can be removed before entering the next automated process, reducing the costs of manual cleaning and waste of downstream materials caused by an increase in scrap rate, as well as the production of non-A grade wafers. This can significantly reduce cost expenditures for battery factories and improve the yield of solar cells.