L-P81W-H7CC-R

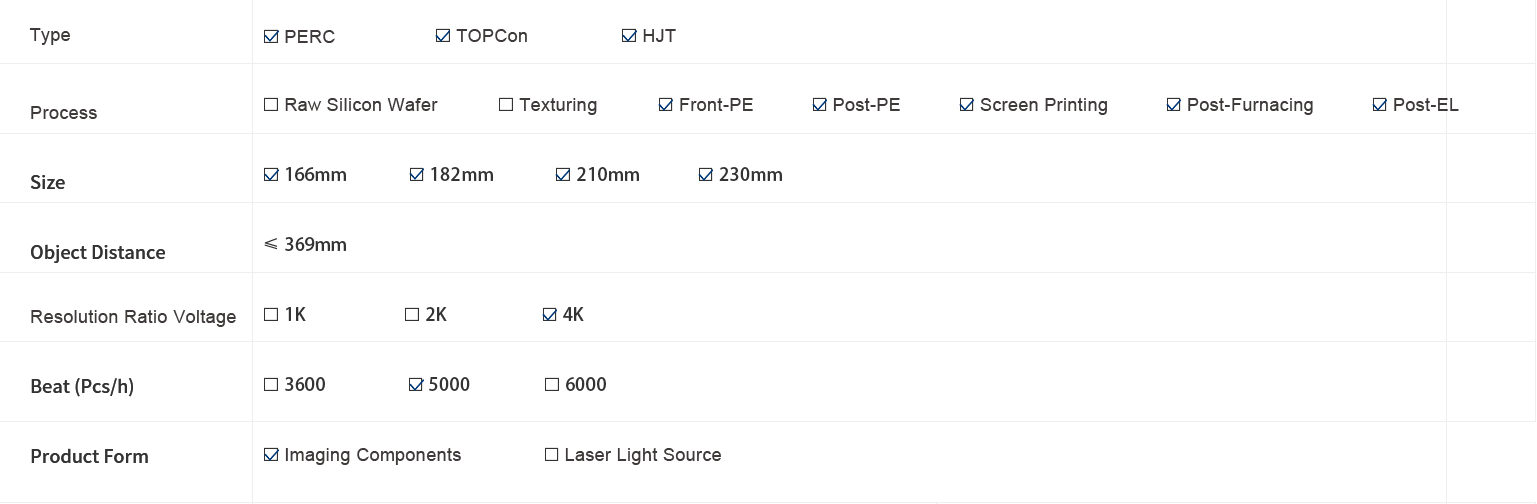

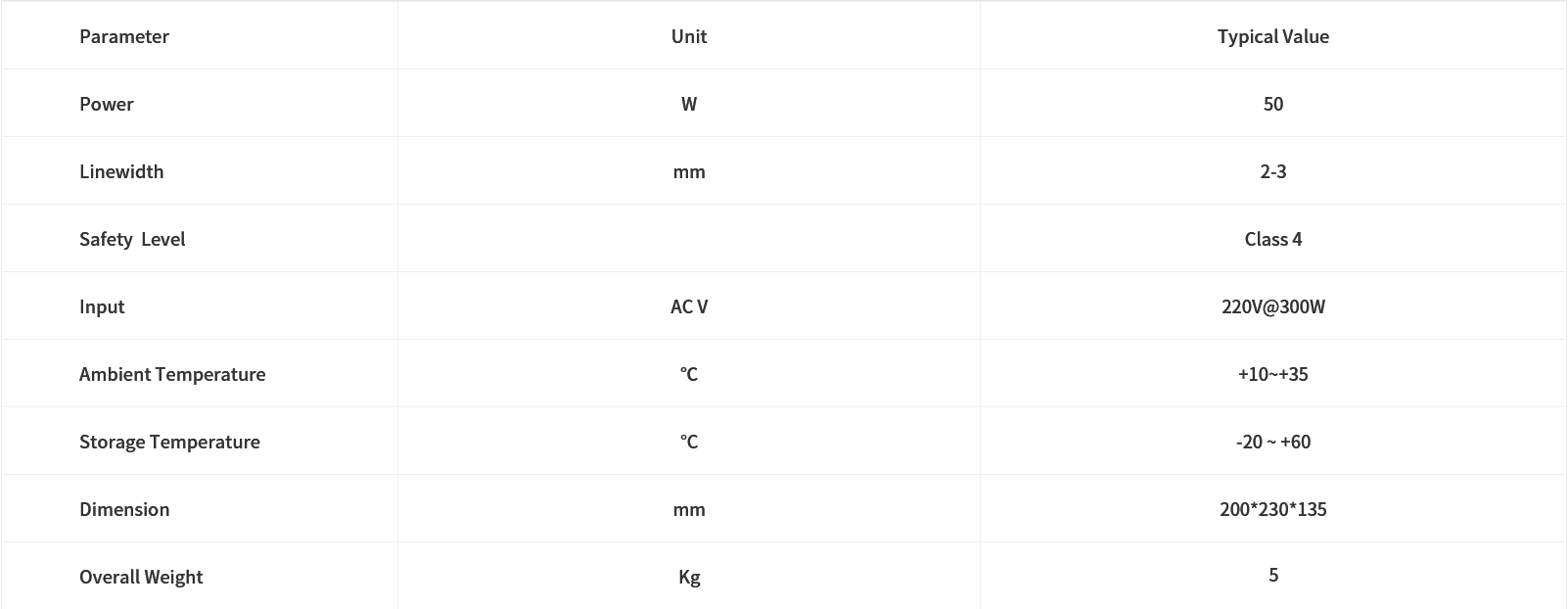

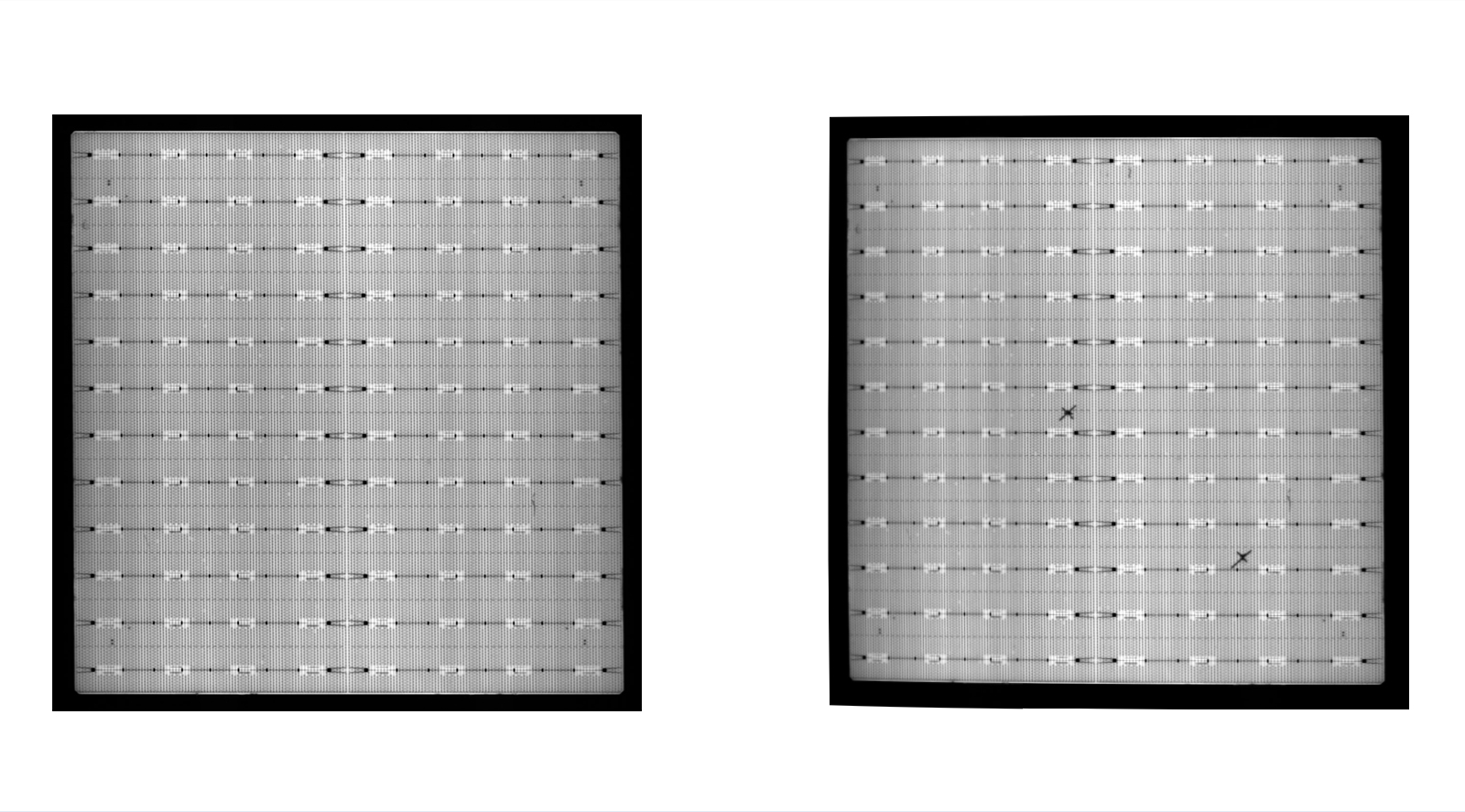

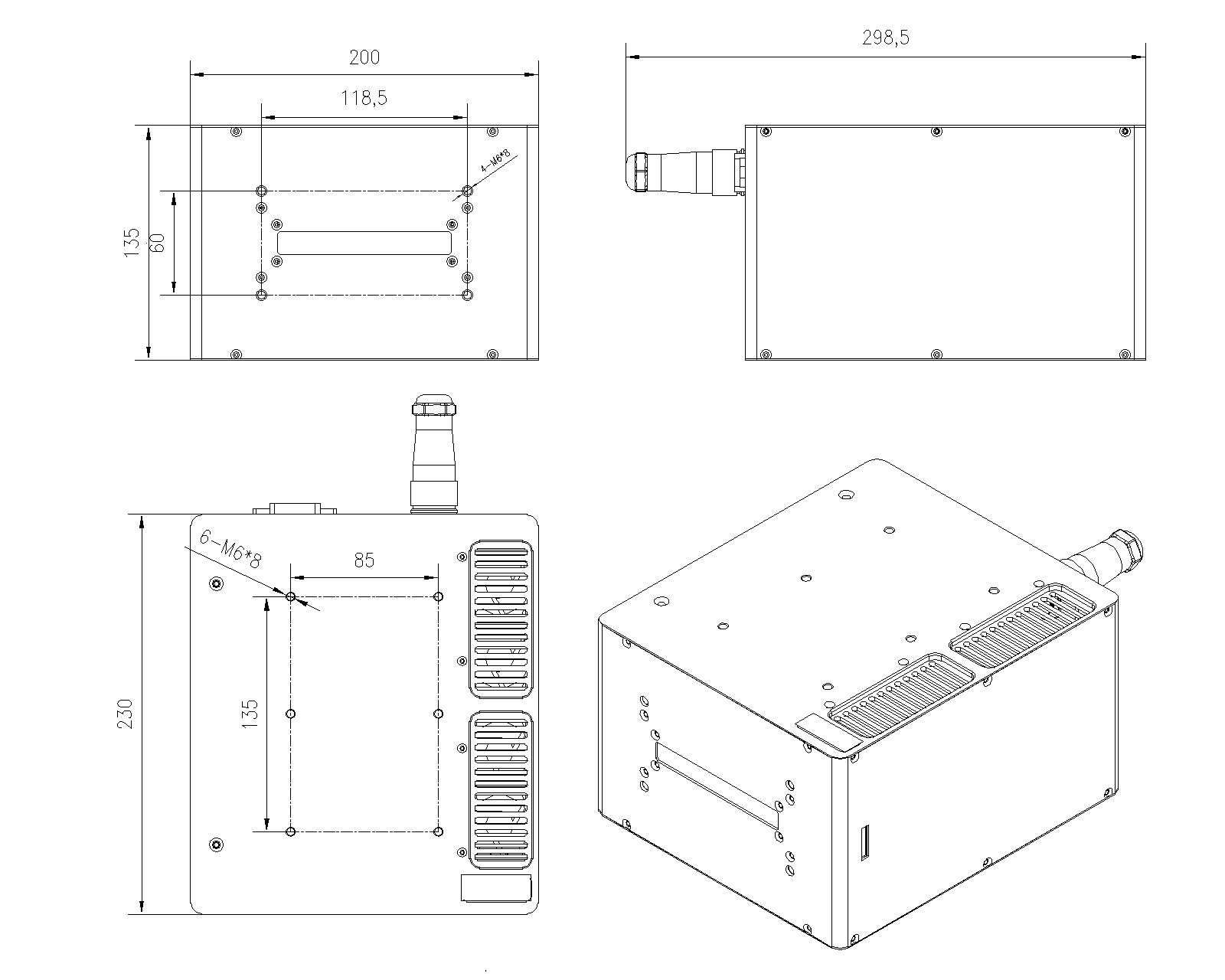

The LPI is used for online PL detection in photovoltaic intelligent manufacturing lines. The defect image is transmitted to the user's PC through the Gigabit network.Users can use image recognition technology to judge and identify defects in imaging, and cooperate with automation to eliminate them.Typical defect types include: hidden cracks, broken edge, black core, concentric circles,scratches, belt marks, and dirty.

The LPI can help users eliminate defective chips in the process to increase the production of A-grade chips, which is a non-contact non-destructive testing method, The detection process does not affect production speed, and can help users identify potential product defects in the process so that adjustments can be made on site in a timely manner, reducing potential waste of raw material costs in the future. The current production field of crystalline silicon batteries has gradually tended towards larger and thinner sizes and thicknesses. In this context, traditional contact testing is difficult to effectively control the fragmentation rate, and laser PL non-destructive testing will become an essential detection method and a standard product for removing defective products in photovoltaic processes.